|

The App

Although I am not limiting myself to Plant Applications projects, I must admit that I have spent almost all of the last 11 years working with Proficy Plant Applications and related Proficy products such as Proficy Historian.

Proficy Plant Applications is a highly customizable, fully... I'll let the folks at GE do the marketing for their product. http://www.ge-ip.com/products/plantapplications-performancemanagement/c491.

Same for Workflow. http://www.ge-ip.com/products/proficy-workflow/p2807

With any system that is highly configurable/customizable it is easy for a project to get out of hand with respect to scope and cost. On the other hand, restrictions on the business, due to missing functionality in a software system, never go over well with end users or management. Somewhere there is a balance between cost of deployment and meeting the business needs/wants/desires. This balance applies to both the software and the implementation project. The more flexible the software, the less out-of-the-box functionality will exist. And the more business requirements, the more the deployment cost. All of these trade offs must be considered throughout the life-cycle of a software system.

I truly believe that Plant Applications strikes the right balance for a software system in all of the work that I have done. That is not to say that it is perfect in every case, but it does provide base functionality at a cost that is orders of magnitude lower than a custom solution, and it allows for the flexibility to provide almost all of the functionality that was required.

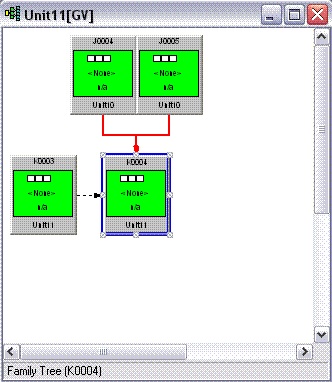

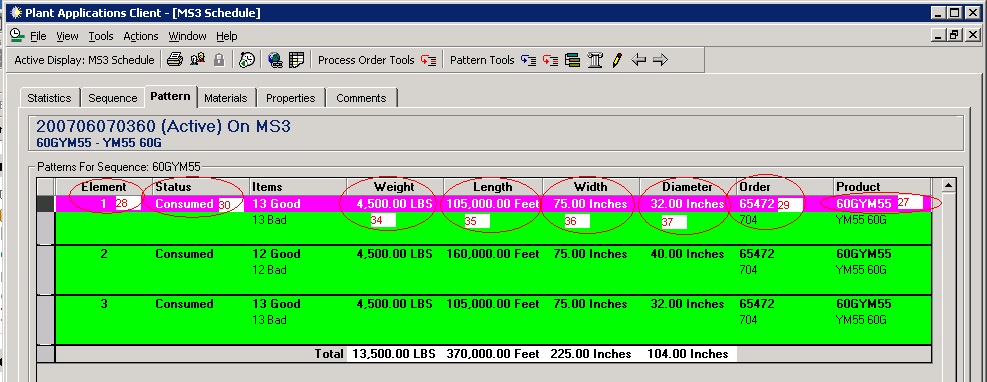

As for the easy of configuration and customization, this depends a lot on what the business needs are and how they get implemented. From my experience, there is an increasing scale of how much customization needs to happen based on the modules of Plant Apps. From the easiest to deploy to the most complicated, my list goes like this: - Quality Management - Efficiency Management - Batch Management - Production Management - Tracking - Schedule Execution

I don't think this order is exclusive to Plant Apps but is just the nature of the functionality. Most Quality data can be captured and reported with a standard set of functionality such as Product Specifications, Simple Alarming, SPC Alarms, Simple Calculations, Audit Trail, E-Signatures, etc. Whereas, there are many ways, depending on the type of manufacturing and order fulfillment, to determine how a schedule should get executed. There are varying levels of on-the-fly changes that can be made, various levels of reporting that must be done on the status of an order, and very complicated interfaces that need to be created.

What I bring to the table is expertise in all of each of these areas. |

2015-08-26 Next Chapter After a long and successful contract with one of the best companies I have ever worked with, I am now moving on to the next chapter of my career. It is always a bittersweet ... |

|

|